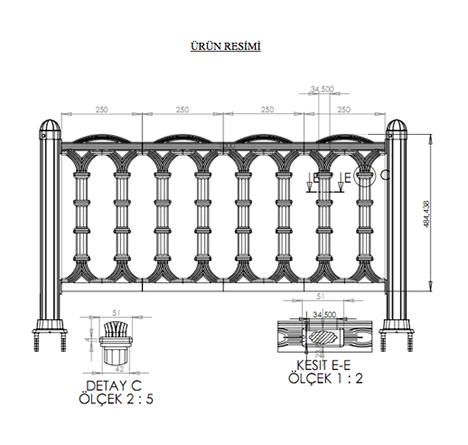

BPC-1071 MODEL FENCE SPECIFICATION

Product Name : Composite plastic fence with aluminum component

Usage Areas : Park – Garden retaining walls, Roadside, Medium refuge separation, Children playground around, Picnic areas, Seaside separation, etc. for

Production Process: Plastic fences are produced from injection-resistant plastic raw material. Due to the natural nature of the plastic, it is resistant to corrosion, discoloration, impacts, cold and heat. Aluminum profiles do not require painting for a long time since they are painted with static paint..

MODULES

1- MODULE 1B: Module with Plastic Cap (Plastic)

2- MODULE 3: Plastic Middle Plug (Plastic)

3- MODULE 4: Plastic Head Plug (Plastic)

4- MODULE 5: Aluminum Casting Base (Casting)

5- MODULE 6: Stand Leg Profile (Aluminum)

6- MODULE 7: Sewing Channel Cover (Aluminum)

7- MODULE 7: Strut Channel Cover Short (Aluminum)

8- MODULE 8-9: Steel Mounting Stud (Steel)

9- MODULE 10: Plastic Stud Nut (Plastic)

10- MODULE 11: Sewing Head (Plastic)

11- MODULE 12: 5 * 8 Steel Screw (Steel)

12-MODULE 13: Super Plastic Imported Anchor (Plastic)

13- MODULE 14: Countersunk Head Steel Screw (Steel)

TECHNICAL SPECIFICATIONS

1-MODULE 3A: Module with plastic cap; High density, polyethylene (PE) raw material, flame retardant and fading chemicals are placed in, 25 cm in the body, produced by injection method fences are passed through the steel stud channels, 1 meter fence or desired distances are obtained according to the project. It has a wall thickness of 16.1 mm, a width of 1000 mm, a height of 484 mm and a weight of 2780 g.

2- MODULE 8-9: Steel Mounting Stud; It is used to bring the bodies together at certain distances and gives the middle closure strength. M 12 is made of worm tooth steel, galvanized, 1040 mm long and weighs 720 grams.

3- MODULE 4: Plastic Head Plug; The plastic modules are inserted between the stud nut and the module. It prevents plastic module flexing and gives aesthetic appearance. 20mm * 10mm ellipse shaped hole to cross the M12 screw in the middle, weight is 3 g.

4- MODULE 3 – Plastic Middle Plug; It prevents the flexing and joining of the plastic modules and the steel stud and provides strength. 20mm * 15mm ellipse shaped hole through the middle M12 screw, weight 5 gr.

5- MODULE 10 – Plastic Stud Nut ; It is mounted on both ends of the steel studs, allowing the assembled fence to be mounted on the upright profile. 24 mm in diameter and 44 mm in width with M12 bolt holes in the middle.

6- MODULE 6 – Stand Leg Profile ; It is made of aluminum and painted in the oven with static powder paint. It is mounted to the concrete floor by means of tripod screws. Diameter 49,8mm length 380 mm, weight 270 g / mt.

7- MODULE 5 – Zinc Alloy Casting Base ; It is made of zinc alloy and painted with static powder paint in the oven. It has a base width of 80 * 80 mm, a height of 55 mm and a weight of 460 gr. There are 4 outer bolt holes and 4 inner bolt holes.

8- MODULE 11- Sewing Head ; It is produced from high density Polyethylene (PE) raw material by putting flame retardant and non-fading chemicals inside. It has a diameter of 54 mm and a height of 50 mm and a weight of 14 g.

9- MODULE 7 – Sewing Channel Cover; It serves to close the unused channels on the posts aesthetically. It is 23.3mm wide, 7.7mm wide and 350mm long. It weighs 89.44gr / m.

10- MODULE 7 – Sewing Channel Cover Short; It is made of aluminum and painted in the oven with static powder paint. It serves to close the unused channels on the posts aesthetically. It is 23.3mm wide, 7.7mm wide and 45mm long. It weighs 130gr / m.

11-MODULE13 – Super Plastic Import Dowel; Imported dowel made of M8 * 65 plastic. Casting base is used for floor mounting.

12- MODULE 12- 5 * 8 Steel Screw; Galvanized screw made of M8 * 75 key head steel. Casting base is used for floor mounting.

13- MODULE 14 – Countersunk Steel Screw; YSB type bolt. It is used to mount the plastic pillar head to the aluminum pillar profile

INSTALLATION

1- Plastic modules of 25 cm are connected to the steel studs by inserting them through the channels of the modules and assembled to the channels in the profile with plastic nuts.

2- 360 degree direction can be provided to the fence by means of channels located on the four sides of the post. In this way, the fence can be turned in four different directions.

3- Plastic fences are fixed to the aluminum profile by means of galvanized steel and smart screws.

4- Aluminum struts are mounted to hard ground with aluminum casting base. 10 cm galvanized steel dowel is used for mounting the cast aluminum base on the ground.

5- The triple steel dowel screws used in the mounting of the aluminum casting base on the hard ground are closed with a plastic cover.

6- Plastic fences should be tiltable up to 45 °.

7- In the middle of aluminum struts, there is Municipality Logo and Advertising entrance panel.